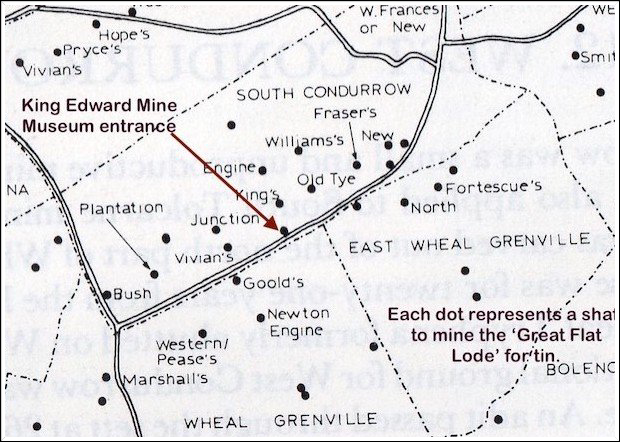

History of King Edward Mine and former South Condurrow Mine

Early Mining History at South Condurrow Mine

Camborne School of Mines Practical Teaching Centre

The set of Californian Stamps at King Edward Mine was made by Messrs Fraser and Chalmers of East Kent, under license and came from the Paris Exposition of 1900. The building that houses the stamps was specially constructed to house them and is now Grade II* listed.

Californian Stamps are now very rare and ours are believed to be the only working set remaining in Europe.

The original Holman Winder went into service at King Edward Mine in 1908, a 10 inch by 15 inch coupled geared twin drum steam hoist. The Holman Winder was used for raising ore from the shaft below the headframe. We believe that this is the only Holman Winding Engine left in the world.

In 1880 John and James Holman (Holman Bros.) were offered the designs of a new rock drill by James McCulloch. The brothers filed a joint patent with McCulloch, and began to manufacture the new drill. It became known as the "Cornish Rock Drill", and achieved great commercial success. The demand grew rapidly and Holman were soon supplying the world market. At King Edward Mine, we have an exhibition of the history of Holman's and examples of Holman equipment.

The restored Holman Steam Winder now runs using compressed air and is demonstrated to our many visitors.